Наши рационализаторы

Innovators have always had and have place to apply their creative efforts. On the plant, innovative movement has always been bringing appreciable benefit. Yet, technical policy, which was outlined by Petro Volodymyrovich Rud during the last meeting of Coordinating Council, must become the responsible task at present; it should be aimed at expense decrease, economical resource usage, seeking of new reserves to increase the efficiency of the plant.

The following measures, which were implemented since the beginning of 2009, have given considerable advantage:

- feed pump for fruit filling on KOMPO line had been remodeled (menders Kryvoruchko V. G., Shvab V. M.), now, fillers are distributed evenly, uninterruptedly;

- piping of 4 tanks for milk storage on the section of whole milk products' production had been reconstructed (mender Talko B. A., tuner Gavrylyuk P. O., electro-gas welder Halylov G. A.), thus, valve number on the pipelines has been decreased and, consequently, milk losses are reduced, along with production efficiency increase;

- washing lines for pipelines, milk storage tank piping in milk acceptance section of the non-fat dried milk department (breakdown mechanic Ruban V. F.), i.e. hand washing of the pipelines had been automated;

- washing lines for non-fat milk feed pipelines from storage tanks to VES (vacuum evaporator system) #1, #2 had been developed and installed (mender Lavrenchuk M. D., breakdown mechanics Bezshkuriy S. V., Kyrylyuk V. I.), thus VES operaton efficiency has been increased significantly, because during the previous pipeline washing VES stood idle;

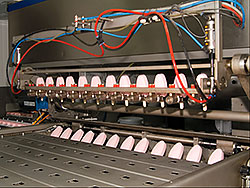

- mix feed construction from freezer to dispenser of line #11 had been modified; freezer operation improvement on the line #12 is planned (mender Kryvoruchko V.G.), which gives a possibility to stabilize ice cream portion weight;

- automated regulation system and hot water temperature control in boiler room had been developed (mechanics CaIE(control and inspection equipment) Vlasyuk S. A., Bochkovskiy P. S.), which will significantly improve hot water supply on the plant and exclude boiler leaking;

- power supply diagram of TS 114 sub user (chief power man Bakun G. P., electrician Osipchuk G. P.), which excludes plant blackouts during sub user's power network breaks.

Due to improvement of reactive energy compensation system in 2008, the economical effect made up 111,070 hrv (executives: chief power man Bakun G. P., electrician Colocolchik Y. G.).

We wish more effective performance of professional skills to our innovators to bring the real benefit to the “Rud” company.

Principal quality engineer Fedorenko L. V.